Vision identify laser marking machine

Model No.: ZWSJ20N

1. Automatically CCD positioning and identifying. With new developed CCD visual system, the objects can be

marked on the appointed area in any position as long as the objects are within the scope of the laser scanner.

It greatly increase the productivity and simplify the process of production. Usually the fiber laser metal

engraving marking machine can work with conveyor belt for production lines which has high requirement for

speed and precision.

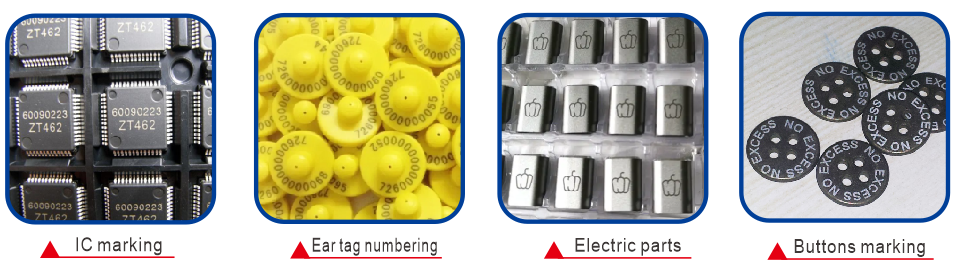

2. CCD camera with 5-megapixel. High resolution, and clearly capture the feature points in real time. Any shape

can be identified, and marking area of the industrial laser marking machine is controlled by software. Clearly

track marking process in computer. This process is especially suitable for small tiny products.

3. Beautiful appearance, compact structure. Rotary system is optional item.

4. The fiber laser metal engraving marking machine’s working format is 110mm×110mm, which can meet the size

requirements of most precision devices.

5. No consumables and wearing parts.

6. CCD camera software supports win7 32-bit and 64-bit computer systems.

7. The industrial laser marking machine supports AI, BMP, DST, DWG, DXF, DXP, LAS, PLT and other graphic

formats.

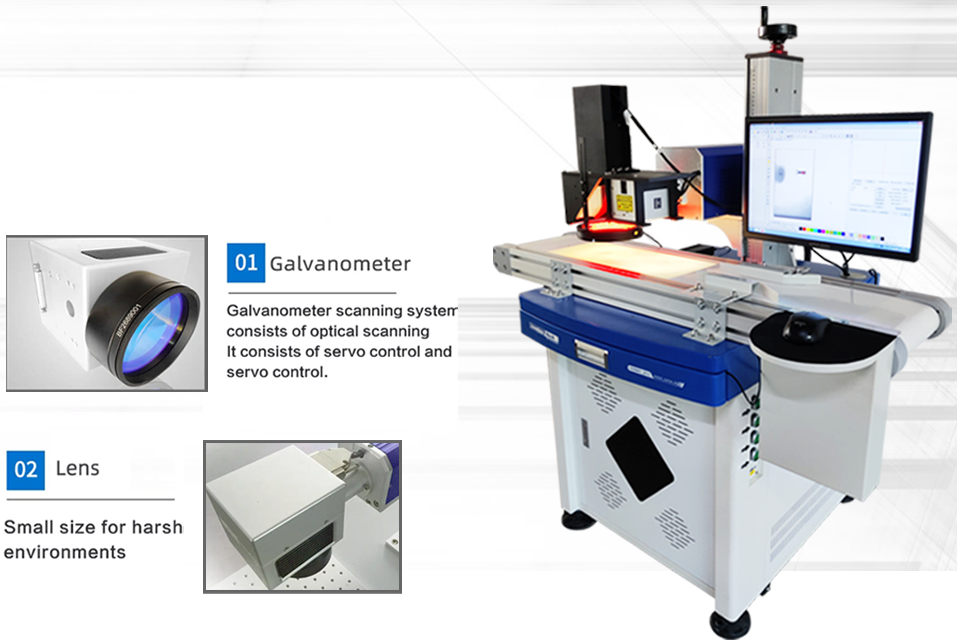

Use high-resolution industrial cameras to shoot dynamic images of workpieces in real time.Confirm the coordinate change of the workpiece, and automatically move the offset coordinate to the correct position through calculation to ensure that the marking is in the correct position.Full fiber optics, no space optics, less failure, good beam quality, small pulse width, more delicate marking graphics,built-in cooling fan can intelligently adjust the wind speed which is convenient for energy saving; fully sealed struc ture, dust-proof and moisture-proof, to ensure long-term op- eration of the machine .Chuangxin/Raycus/Lianpin lasers are optional

Full fiber optics, no space optics, less failure, good beam quality, small pulse width, more delicate marking graphics, built-in cooling fan can intelligently adjust the wind speed which is convenient for energy saving; fully sealed struc ture, dust-proof and moisture-proof, to ensure long-term op- eration of the machine .

| |

1.Quality Control Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery. 2.OEM Service Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required. |